Revealing Superior Top Quality Komatsu Undercarriage Parts for Enhanced Machinery Efficiency

Explore Undercarriage Parts for Your Machinery Requirements

Preserving the undercarriage of your machinery is a crucial element usually forgot till concerns arise. From excavators to bulldozers, the undercarriage plays a vital duty in the total efficiency and long life of hefty devices. Recognizing the elements that comprise the undercarriage and the importance of choosing the best parts is key to making certain smooth operations and cost-efficient upkeep. As we discover the globe of undercarriage parts for machinery needs, a much deeper understanding right into the complexities of this essential system will certainly unravel, shedding light on the structure that supports the efficiency of your tools.

Relevance of Undercarriage Upkeep

Normal upkeep of undercarriage components is critical for making certain optimal performance and durability of equipment. The undercarriage of hefty devices, such as excavators, excavators, and track loaders, plays a vital duty in sustaining the weight of the equipment, supplying stability on various surfaces, and enabling smooth procedure - komatsu undercarriage parts. Ignoring undercarriage maintenance can bring about expensive repairs, lowered effectiveness, and potential security threats

Routine evaluations of undercarriage parts, such as track chains, rollers, idlers, and gears, are vital to recognize deterioration at an early stage. Resolving problems without delay can avoid more damage to the undercarriage and other components of the equipment. Appropriate cleansing of undercarriage components is additionally required to get rid of dirt, debris, and various other impurities that can speed up wear and deterioration.

Routine lubrication of undercarriage parts is another essential aspect of maintenance to make certain smooth movement and decrease friction in between parts. Additionally, tracking the usage hours and keeping upkeep documents can aid in scheduling timely substitutes and lengthening the general life-span of the machinery. By prioritizing undercarriage upkeep, tools owners can optimize efficiency, lessen downtime, and inevitably reduce repair service costs over time.

Kinds Of Undercarriage Components

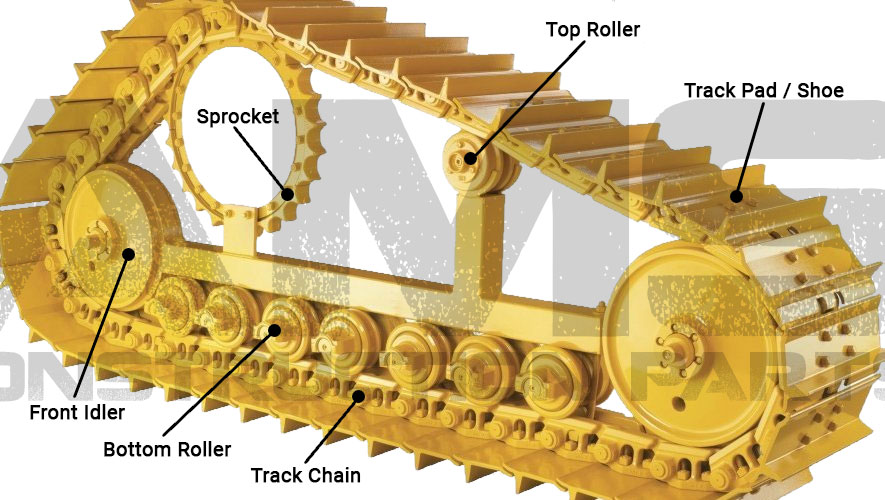

Maintenance of undercarriage parts is essential for machinery long life; comprehending the various types of undercarriage elements is vital for efficient upkeep practices. Undercarriage parts differ depending on the sort of equipment and its desired use. Common types of undercarriage parts include track chains, track shoes, rollers, idlers, sprockets, and track frameworks.

Track chains are responsible for pushing the equipment onward and sustaining the weight of the equipment. Track shoes supply grip and shield the track chain from wear and tear. Rollers assist in weight distribution and track support, while idlers help maintain correct track tension. Gears involve with the track chain and transfer power to relocate the equipment. Track frames serve as the structure for the whole undercarriage setting up, attaching all the parts together.

Routine examination and upkeep of these undercarriage parts are vital to stop expensive repair work and downtime. By recognizing the feature of each kind of undercarriage part, machinery operators can make certain optimal performance and extend the life-span of see their tools.

Aspects to Take Into Consideration When Choosing Parts

Another vital aspect is compatibility with the certain machinery model. Each piece of machinery might have special demands for undercarriage parts, consisting of dimension, design, and requirements. Making certain that the components work with the machinery will help protect against functional issues and premature wear.

Additionally, it is necessary to take into consideration the operating problems in which the machinery will certainly be made use of. Aspects such as terrain, climate condition, and usage regularity can all impact the wear and tear on undercarriage components. Choosing components that are designed to hold up against the details operating problems can help lengthen the life of the machinery and lower maintenance prices in the future.

Advantages of High-Quality Undercarriage Parts

High-grade undercarriage parts play an important function in boosting equipment performance and prolonging its functional durability. One of the main advantages of utilizing high-quality undercarriage parts is improved effectiveness.

Additionally, top quality undercarriage components add to cost savings in the long run. While the preliminary investment may be greater compared to common parts, the longevity and longevity of costs parts decrease the demand for frequent replacements and repair services. This not just click over here reduces downtime yet also reduces upkeep prices, ultimately resulting in higher general performance and profitability for services that count on hefty machinery.

Furthermore, remarkable undercarriage components enhance safety by decreasing the danger of unanticipated failings or crashes. The raised stability and performance offered by high-grade parts create a safer working atmosphere for machinery operators and those operating in close distance to the devices. Eventually, selecting top notch undercarriage components is a critical choice that generates many advantages in terms of performance, longevity, safety, and cost-efficiency.

Tips for Extending Undercarriage Lifespan

To maximize the long life of undercarriage parts for equipment, applying positive treatment practices is necessary for ensuring ideal efficiency and sturdiness. Over-tightened tracks can lead to increased anxiety on the undercarriage, while loosened tracks can trigger imbalance and irregular wear.

Running the machinery within suggested guidelines, such as preventing excessive speeds or overloading, can also add to expanding the undercarriage life expectancy. By adhering to these pointers, equipment proprietors can make certain ideal efficiency and longevity of their undercarriage parts.

Conclusion

Finally, keeping the undercarriage components of equipment is crucial for ideal performance and durability. By recognizing the various sorts of undercarriage components and aspects to think about when picking them, organizations can ensure their devices operates effectively. Buying top quality undercarriage parts not only boosts efficiency however additionally decreases downtime and costly repair work. By following proper upkeep techniques, services can prolong the lifespan of their undercarriage components, inevitably saving money and time in the lengthy run.

Normal maintenance of undercarriage components is essential for guaranteeing optimum performance and longevity of equipment.Maintenance of undercarriage components is important for equipment long life; comprehending the various kinds of undercarriage components is vital for effective upkeep practices.When choosing undercarriage components for machinery, it is important to think about numerous factors to guarantee ideal efficiency and long life.To make the most of the long life of undercarriage components for machinery, carrying out aggressive treatment techniques is vital for making certain optimal performance and durability. By following these suggestions, equipment proprietors can next make sure optimum efficiency and toughness of their undercarriage components.